Material

Double-Ended Alloy 800/840

Temperatures

1800°F or 982°C

Densities

45 W/in2 or 6.9 W/cm2

Material

Double-Ended Stainless Steel

Temperatures

350°F or 175°C

Densities

60 W/in2 or 9.3 W/cm2

Material

Double-Ended Steel

Temperatures

750°F or 400°C

Densities

45 W/in2 or 6.9 W/cm2

Material

Singled-ended Alloy 800/840

Temperatures

1600°F or 870°C

Densities

45 W/in2 or 6.9 W/cm2

Material

Single-Ended Stainless Steel

Temperatures

1200°F or 650°C

Densities

60 W/in2 or 9.3 W/cm2

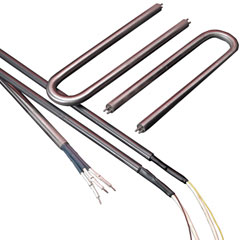

Available in single- or double-ended termination styles, the versatile and economical WATROD tubular heating element lends itself to virtually the entire range of immersion and air heating applications.

The single-ended WATROD tubular heater design has both terminals at one end. The opposite end is sealed. Flexible lead wires are 12 in. (305 mm) crimp connected to the terminal pin and have silicone-impregnated fiberglass oversleeves.

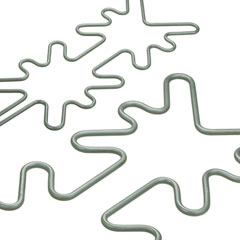

The double-ended WATROD, with its round cross-sectional geometry, are highly adaptable for bending—especially when bending is performed in the field. Watlow’s double-ended MULTICOIL tubular elements offer various combinations of resistor coils and thermocouples inside one sheath. They have the ability to sense the heater’s internal temperature accurately every time, or offer three-phase capability in one element.

Both single- and double-ended WATRODs share many construction features delivering long life—the resistance wire is centered in the heater sheath and electrically insulated with compacted, high-grade magnesium oxide for superior heating performance.

WATROD tubular heating elements have a variety of mounting and termination options making them highly popular among industrial customers.